Asbestos Removal Tools

Understanding Asbestos Removal: Tools, Safety, and the Evolution of Techniques

Asbestos, a term that strikes concern in the hearts of homeowners and construction professionals alike, has a notorious legacy. Once hailed for its heat resistance and strength, asbestos is now infamous for its health hazards, including serious lung conditions and cancers. The removal of asbestos, a task that calls for meticulous attention and specialised tools, is governed by strict regulatory standards to ensure safety. This blog post delves into the essential tools and protective gear required for safe asbestos removal, illuminating their roles and importance.

Personal Protective Equipment (PPE) for Asbestos Removal

The Shield Against Asbestos: Respirators

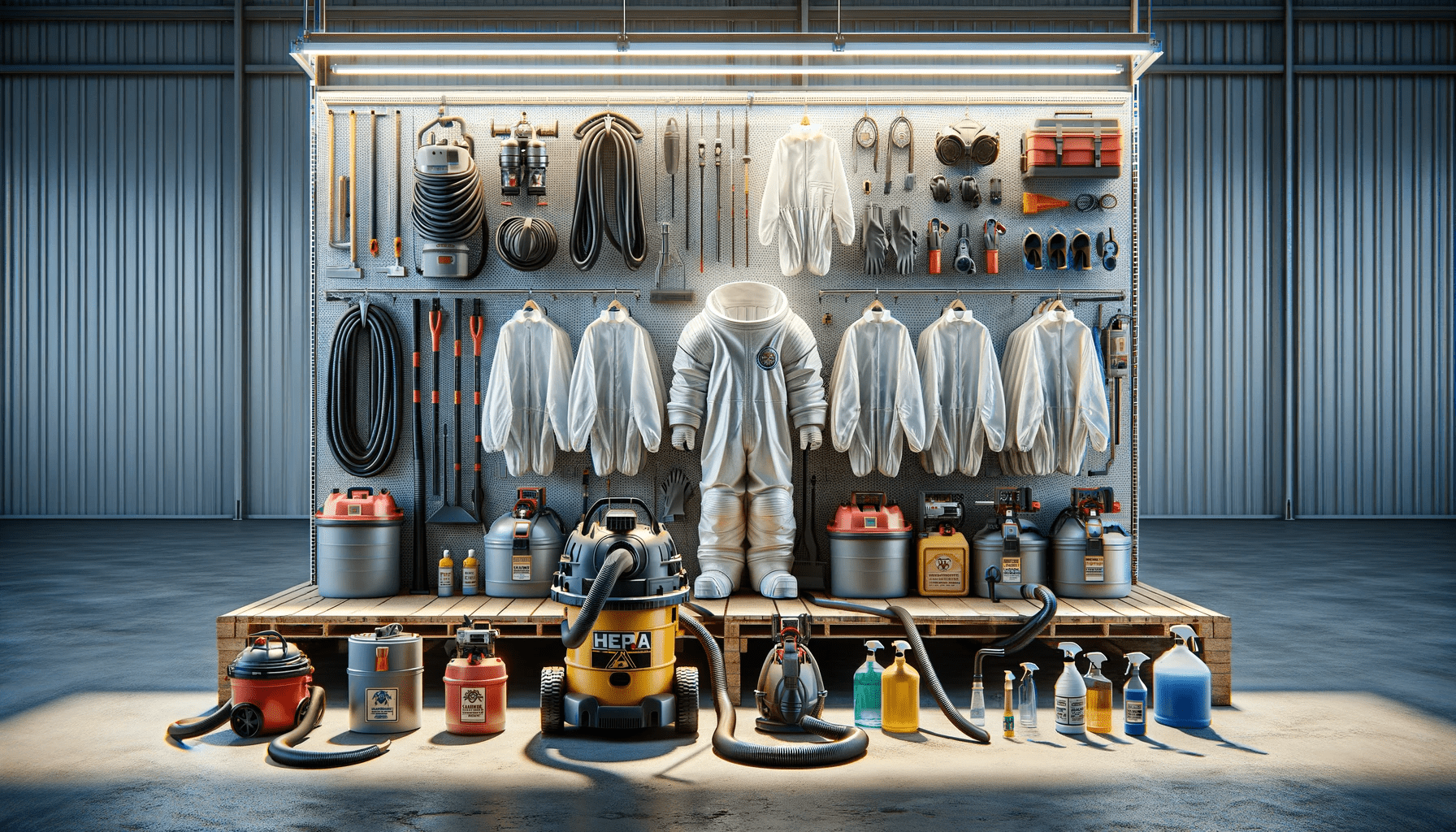

When dealing with asbestos removal, the primary line of defence is a high-quality respirator. Respirators designed for asbestos work must be equipped with P2 or P3 filters capable of trapping microscopic asbestos fibres. It’s not just about having a respirator; it’s also about ensuring it fits correctly and forms a seal against the face. Regular maintenance, including checking for wear and tear and replacing filters, is crucial.

Full Coverage: Protective Clothing and Gloves

Disposable coveralls, often with a hood, safeguard the skin and prevent asbestos fibres from clinging to everyday clothing. Similarly, gloves are a necessity. They should be robust yet flexible, allowing for precise movements while handling tools and materials. As with other PPE, the key is to ensure no asbestos fibres can penetrate or linger on the surface.

Eye Protection: More Than Just Safety Glasses

While asbestos fibres primarily pose a risk when inhaled, protecting one’s eyes is equally important. Safety goggles that enclose the entire eye region are preferred over standard safety glasses. These goggles prevent fibres from entering around the sides, which is essential during intensive removal activities.

Asbestos Removal Tools: Hand Tools and Equipment

The Essentials: Hand Tools

A range of hand tools are indispensable in asbestos removal. These include scrapers for removing asbestos-containing materials (ACMs) and sprayers for dampening asbestos to prevent fibre dispersion. Choosing tools that are easy to decontaminate—typically those with smooth, non-porous surfaces is important.

The HEPA Standard: Vacuums and Air Filtration

High-Efficiency Particulate Air (HEPA) vacuums play a pivotal role in asbestos removal. Unlike regular vacuums, HEPA vacuums trap tiny asbestos fibres, preventing them from re-entering the atmosphere. Similarly, negative air machines, equipped with HEPA filters, create a negative pressure environment, ensuring fibres do not spread to uncontaminated areas.

Sprayers: Keeping Asbestos Under Control

Water sprayers are used to keep asbestos fibres from becoming airborne. These should be used carefully to moisten asbestos without creating water damage or electrical hazards. The right balance is key to effective and safe asbestos removal.

Advanced Tools for Large-Scale Asbestos Removal

Large-Scale Asbestos Removal: The Necessity for Advanced Tools and Machinery in Commercial Projects

The scale and complexity of asbestos removal projects can vary significantly. When it comes to larger-scale operations, such as the stripping of asbestos from commercial buildings or old factories, the requirement for more advanced tools and machinery becomes critical. These tools not only enhance efficiency but also ensure the safety of the removal process is upheld to the highest standards.

The Role of Enclosures and Containment

In significant asbestos removal projects, creating a contained environment is vital. Temporary enclosures, often made from thick plastic sheets, are erected around the removal area. These structures serve to contain asbestos fibres, preventing them from spreading to uncontaminated zones. Inside these enclosures, negative air pressure units are commonly used to further control the spread of fibres.

Decontamination Units: Ensuring Safety Beyond the Work Area

Decontamination units are another essential aspect of large-scale asbestos removal. These units, typically segmented into the clean, shower, and dirty rooms, are critical for ensuring workers do not carry asbestos fibres outside the work area. These facilities allow for the safe removal of protective gear and thorough decontamination of workers, which is a crucial step in preventing asbestos exposure.

Specialised Tools: Going Beyond the Basics

For more extensive removal tasks, specialised tools like pneumatic cutters and industrial vacuums come into play. These tools are designed to handle larger quantities of asbestos materials efficiently, ensuring quick and effective removal while minimising the release of fibres into the air.

Asbestos Waste Disposal Methods and Tools

Critical Phase: Proper Disposal of Asbestos Waste

The final and equally crucial phase in asbestos removal is the disposal of asbestos waste. Proper disposal methods are not just a legal requirement but imperative for environmental safety.

Containment and Transportation: Bags and Containers

Asbestos waste must be securely contained in specialised bags or containers clearly labelled as hazardous material. These containers are designed to be sturdy and leak-proof, ensuring safe transportation to designated disposal sites.

Air Monitoring: A Critical Tool in Waste Disposal

Throughout the disposal process, air monitoring plays a vital role. Specialised air monitoring tools are used to detect the presence of asbestos fibres in the environment, ensuring that the disposal process has not led to any contamination. This monitoring is crucial for worker safety and environmental protection.

Emerging Technologies and Future Tools in Asbestos Removal

Technological Advancements in Asbestos Removal: Towards Safer and More Efficient Methods

As we advance in technology, the tools and techniques used in asbestos removal are also evolving. This evolution holds the promise of increased safety, efficiency, and possibly even complete automation of some aspects of asbestos removal in the future.

Innovations in Safety and Efficiency

Emerging technologies in robotics and automation are being explored for use in asbestos removal. These innovations could minimise human exposure to asbestos, enhancing safety significantly. Additionally, developments in materials science may lead to more effective protective equipment and containment materials.

The Future of Asbestos Removal

The future of asbestos removal may see the integration of advanced sensors and AI technology. These could provide real-time data on asbestos fibre concentrations, enabling more precise and efficient removal processes. As these technologies develop, they could revolutionise the way asbestos removal is conducted, prioritising safety and efficiency more than ever.

In conclusion, the world of asbestos removal is a landscape marked by a range of specialised tools and equipment, each playing a critical role in ensuring the safe and effective removal of this hazardous material. From personal protective equipment to advanced machinery for large-scale projects and the forward march towards technological innovation, the field is constantly evolving. This evolution enhances safety and efficiency and brings hope for a future where asbestos can be handled with minimal risk, protecting both the workers involved and the environment at large.